Since 2004, HUDA has been focusing on innovation in environmental test machine, battery test machine, rubber and plastic testing machines, UTM, etc., with rich experiences and a proactive attitude.

Lab test machines manufacturers & suppliers

Battery Crush Nail Penetration Test Machine

| Share | |

|---|---|

| Categories | Battery Test Machine |

| Brand | HUDA Test Machine Manufacturer |

| Model | HUD-H212 |

| Inner dimensions | 520x450x560mm |

| Outside dimensions | 800x700x1720mm |

| Drive mode | Servo motor drive |

| Force range | 1~20kN |

| Extrusion stroke | 250mm |

| Material of inner chamber | SUS#304, thickness 1.2mm |

| FOB port | shenzhen |

| Terms of Payment | L/C, D/A, D/P, T/T, Paypal |

| Update Time | Feb 18,2026 |

Battery Crush Nail Penetration Test Machine is suitable for simulating the squeezing and acupuncture of various batteries during use, transportation, storage or disposal under certain temperature conditions. And judging the battery safety performance.

Test Standard

UN 38.3 "United Nations Manual of Transport Tests and Standards for Dangerous Goods"

IEC62133 "Battery (group) composed of batteries and safety requirements for portable equipment"

UL 1642:2012 "Lithium Battery Standard"

GB/T 31485-2015 "Safety requirements and test methods for power batteries for electric vehicles"

GB/T 31241-2014 "Safety requirements for lithium-ion batteries and battery packs for portable electronic products"

Battery should be tested in an environment of 20℃±5℃. Place the battery connected to the thermocouple (the contact of the thermocouple is fixed on the large surface of the battery) in a fume hood, and pierce the largest surface of the battery with a non-corrosive steel needle with a diameter of 2-8mm at a speed of 25mm/s Keep it at the center of the battery for any time and observe the test results.

The battery is qualified as no disintegration, no rupture, and no fire.

Servo motor drive; | |

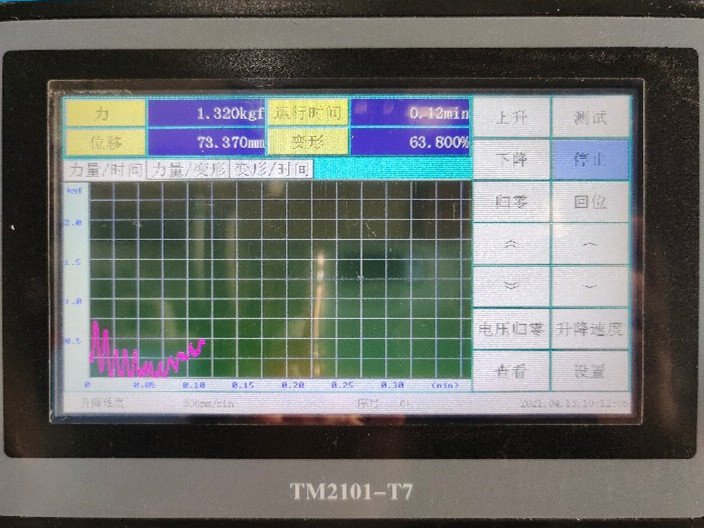

2. Control method | PLC touch screen control; |

3. Force range | 1~20kN; |

4. Extrusion stroke | 250mm; |

5. Force value display | touch screen display; |

6. Extrusion head | Extrusion head area ≥20cm²; |

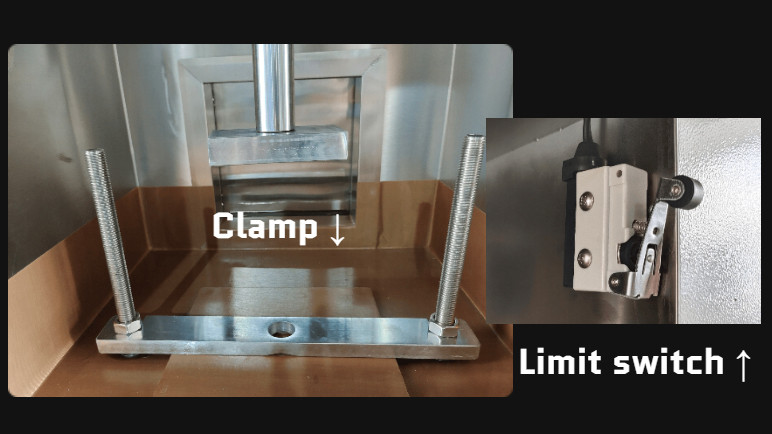

7. Extrusion degree | Extrusion pressure reaches 13±0.2kN, keep for 1min; |

8. Test space | 200x200x200mm (width x depth x height) |

9. External material | A3 steel plate and painted, thickness 1.5mm; |

10. Material of inner box | SUS#304, thickness 1.2mm; |

11. Steel needle | φ2mm~φ8mm high temperature resistant steel needle, the length is 100mm (optional); |

12. Inner dimensions | 520x450x560mm (width x depth x height); |

13. Outside dimensions | 800x700x1720mm (width x depth x height, including door lock); |

14. Pressure relief door size | 200x200mm; |

15. Smoke exhaust pipe | diameter φ100mm, located at the back of the box; |

* Safety Alarm Device

Electrical leakage

Over voltage

Overload and over temperature

Over current protection

Abnormal sound and light alarm

Smoke alarm lamp

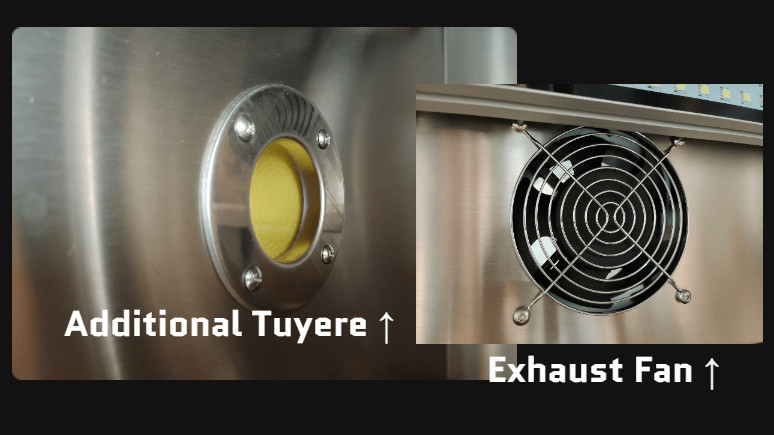

* Exhaust system

It is equipped with an exhaust fan and an duct at the back of test chamber. There is an air inlet on the left side of the chamber. After the test, the air inlet can be opened to achieve rapid exhaust of the smoke in the chamber.

* Pressure Relief Port

Located at the back of test chamberφ200mm, when the pressure inside of chamber is large, the safety door will be opened automatically, it can release the pressure inside of chamber

Easy to operate

SUS#304, thickness 1.2mm

Explosion-proof glass +

protective steel mesh

- Phone

- *Title

- *Content

- Electric Vehicle Recalls and SafetyWith the gradual promotion of new energy vehicles, the number of recalls and complaints is also gradually increasing.

- China Brand DayChinese brand, shared by the world...