Since 2004, HUDA has been focusing on innovation in environmental test machine, battery test machine, rubber and plastic testing machines, UTM, etc., with rich experiences and a proactive attitude.

Lab test machines manufacturers & suppliers

Three Zones Thermal Shock Test Chamber 丨 High-Low Temperature Test Equipment

Thermal shock testing subjects a product to alternating extremes of high and low temperatures in order to observe changes in the product’s characteristics and failure occurrences caused by different materials and thermal expansion.

Test method | Pneumatic operated door switch 3 chambers |

Inner dimension (W*D*H) | 500*450*450mm |

External dimension (W*D*H) | 1380*1370*1980mm |

Temperature range | -40 ~ +80℃ |

High temperature chamber pre-heating range | 60 ~ 100℃ |

Heating speed | +60→+100℃ about 10 minutes |

Low temperature chamber pre-cooling range | -65 ~ 0 |

Cooling speed | Ambient →-65℃ about 65 minutes |

Temperature deviation | ±3℃ |

Thermal recovery time | Thermal recovery time |

External material | Antirust processing cold-rolled steel sheet |

Internal material | SUS#304 stainless steel |

Thermal insulation material | Polyurethane foam and fiberglass |

Coolant | R404A / R23 |

Cooling method | Air cooling |

Pressure | 0.2 - 0.5Mpa |

Power supply | Three phase, 380V, 50Hz |

High temperature chamber:

1, Including three parts: heater, draught fan and air duct valve

2, Draught fan cyclically stirs hot air through heater

3, The basket with testing product drive to high temperature range when doing high temperature impact test.

Low temperature chamber:

1, Including four parts: evaporator, energy storage piece, draught fan and air duct valve

2, Draught fan cyclically stirs cold air through evaporator and energy storage piece.

3, The basket with testing product drive to low temperature range when doing low temperature impact test.

Drive device:

Pneumatic cylinder: drive basket with testing product to high and low temperature chamber

Air compressor: Provide the compressed air for driving pneumatic door (supplied by buyer)

Refrigerating device:

Cooling system: complex overlapping efficient cryogenic loop system

Compressor: Bock compressor

Refrigerant: environmental protection refrigerant R23/R404A

Condensation: Stainless steel welded plate heat exchanger

Controller:

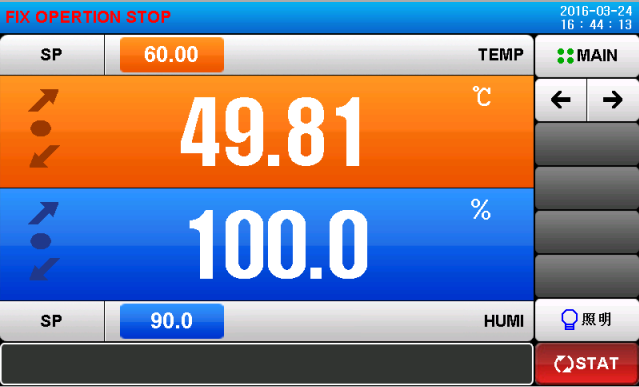

Operate interface: PLC controller, touch screen

Program memory capacity: 100 groups

Setting range: Time: 1 minute ~ 99 hour 59 minute, cycles: 1~ 9999cycles

Resolution: temperature: 0.01 ℃

Input: T thermocouple

Control method: PID auto calculation control

Additional functions:

Timer, over temperature and power failure protection, alarm, record test curve, emergency stop, display test time

Standard configuration: indication lamp of test chamber, time meter, test hole for wire routing, 6pcs castor, 4pcs adjust wheel.

Safety device:

Power overload protection

Leakage protection

Control circuit overload protection

Short-circuit protection

Compressor overload protection

Ground protection

Over temperature protection

Audible and visual alarm

- Phone

- *Title

- *Content

- Electric Vehicle Recalls and SafetyWith the gradual promotion of new energy vehicles, the number of recalls and complaints is also gradually increasing.

- China Brand DayChinese brand, shared by the world...