Since 2004, HUDA has been focusing on innovation in environmental test machine, battery test machine, rubber and plastic testing machines, UTM, etc., with rich experiences and a proactive attitude.

How to screen electronic components?

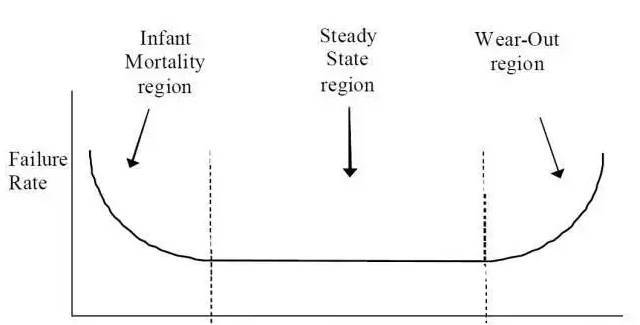

Electronic components are the basis of the whole machine. During the manufacturing process, it may cause failures related to time or stress due to its inherent defects or improper control of the manufacturing process. In order to ensure the reliability of the entire batch of components and meet the requirements of the complete machine, the components that may have initial failures under the conditions of use must be removed. The process of component failure rate changing with time can be described by a failure rate curve similar to a "bathtub curve". The early failure rate decreases rapidly with the increase of time, and the failure rate during the service life (or accidental failure period) is basically not Change.

The inherent reliability of electronic components depends on the reliability design of the product. In the manufacturing process of the product, due to human factors or fluctuations in raw materials, process conditions, and equipment conditions, the final products cannot all achieve the expected inherent reliability.

In each batch of finished products, there are always some potential defects and weaknesses in a part of the products, and these potential defects and weaknesses are manifested as early failures under certain stress conditions. The average life of components with early failure is much shorter than that of normal products.

Therefore,screening is an important means to ensure reliability.

How to screen electronic components?

1. High temperature storage

Most of the failures of electronic components are caused by various physical and chemical changes in the body and on the surface, and they are closely related to temperature. After the temperature rises, the chemical reaction speed is greatly accelerated, and the failure process is also accelerated. So that the defective components can be exposed in time and removed.

High-temperature screening is widely used in semiconductor devices. It can effectively eliminate devices with failure mechanisms such as surface contamination, poor bonding, and defective oxide layers. Usually stored at the highest junction temperature for 24 to 168 hours.

2. Power electric aging

When screening, under the combined action of thermoelectric stress, it can well expose a variety of potential defects in the body and surface of components, which is an important item of reliability screening.

Various electronic components are usually aged for several hours to 168 hours under rated power conditions. Some products, such as integrated circuits, cannot be changed arbitrarily. However, high-temperature working methods can be used to increase the working junction temperature and reach a high stress state. The electrical stress of the components should be selected appropriately, which can be equal to or slightly higher than the rated conditions, but no new failure mechanism can be introduced.

Power aging requires special test equipment, and its cost is high, so the screening time should not be too long. Civil products usually take several hours, military high-reliability products can choose 100, 168 hours, and aerospace-grade components can choose 240 hours or even longer periods.

3. Temperature cycle

Electronic products will encounter different environmental temperature conditions during use. Under the stress of thermal expansion and contraction, components with poor thermal matching performance are prone to failure. The temperature cycle screening utilizes the thermal expansion and contraction stress between extreme high temperature and extreme low temperature, which can effectively eliminate products with thermal performance defects. Commonly used screening conditions for components are -55~+125℃, cycle 5-10 times.

Huda focus on temperature & humidity test chamber with 17 years and we had provide lad solutions for more than 150+ countries.

If any question about these,please contact us!

Temperature & Humidity Test Chamber https://www.hudatest.com/pid18117053/Programmable-Temperature-And-Humidity-Test-Environmental-Climate-Chambers-Climatic-Chamber.htm

Thermal Shock Test Chamber

https://www.hudatest.com/pid18121229/Three-Zones-Thermal-Shock-Test-Chamber.htm

Rapid Temperature Change Test Chamber

- Electric Vehicle Recalls and SafetyWith the gradual promotion of new energy vehicles, the number of recalls and complaints is also gradually increasing.

- China Brand DayChinese brand, shared by the world...