Thermal Shock Test Chamber’s Main Working System

Thermal Shock Test Chamber’s Main Operating System

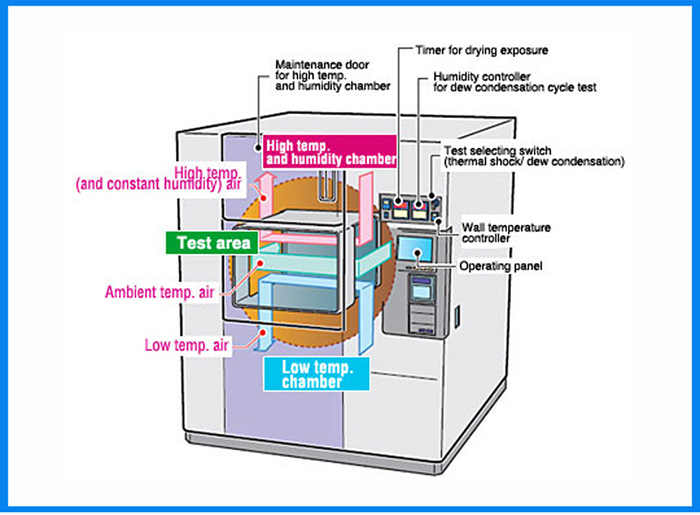

Thermal Shock Test Chamber is used to test the bearing extent of the material structures and composite material in an instant and continuous high temperature and extremely low temperature environment, which is in the shortest time to test its thermal expansion and contraction caused by chemical change or physical harm.But do you know how it works?There are three main working system .

Refrigeration system

Refrigeration system and compressor: a two yuan cascade freon refrigeration system consisting of a COPELANDBAN semi hermetic compressor in Germany. Cascade refrigeration cycle system comprises a high pressure and a low pressure refrigeration cycle, the connecting container for evaporative condenser, evaporator condenser evaporator will function as low cycle as a cycle of high pressure condenser.

The process is as follows: the refrigerant compressed to high pressure compressor power consumption by adiabatic, exhaust temperature, refrigerant through the condenser after isothermal and the surrounding medium heat exchange of the heat to the surrounding medium. The refrigerant is done by the adiabatic expansion of the shut-off valve, when the refrigerant temperature is lowered. This cycle goes round and round so as to cool down.

Air conditioning system

Air conditioning: forced circulation ventilation, balanced temperature regulation (BTC). The method not only refers to the continuous operation of the refrigeration system, the control system to control the output of the heater according to the set temperature point through PID automatic operation and output, and finally achieve a dynamic balance.

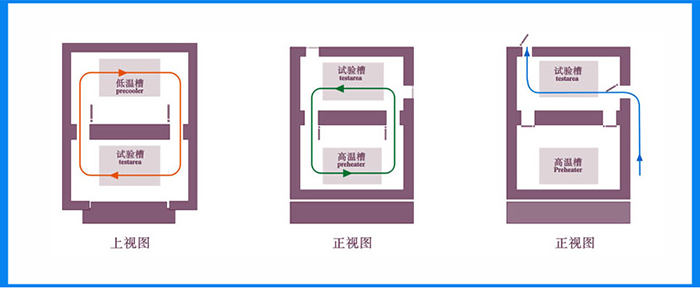

Air circulation device: built-in air circulation duct, and the long axis of stainless steel fan, refrigerator and energy efficient use of the regulating system, effective heat exchange through efficient ventilation machine, to achieve the purpose of temperature change. By adjusting the air plug of the air outlet, the temperature uniformity of the test box is greatly improved.

Air cooling method: multistage diaphragm type air heat exchanger; air heating mode: high quality nickel chromium wire electric heater.

Control system

Control system using intelligent control software system, combined with automatic cooling and heating system working conditions, so as to ensure the high precision control in the whole temperature range, and achieve the purpose of saving energy and reducing consumption.

Control device: the controller adopts imported programmable PLC and imported LCD color LCD touch screen dual loop temperature control system, the control of imported color LCD touch display screen control display screen is adopted in the controller Chinese operation display interface display, can display and set the test parameters, curve, total running time, total operation time, heater the working state and calendar time etc.. The control program is programmed by man-machine dialogue. The interface is friendly, and the automatic operation of the refrigerator can be realized only by setting the temperature.

Huda has over 10 years of industry experience in designing and manufacturing environmental chambers and temperature controlled products.Huda also manufactures a variety of environmental chambers that simulate other climatic conditions such as rain, wind, dust and sun.If you have any questions,contact us please.

Huda has over 10 years of industry experience in designing and manufacturing environmental chambers and temperature controlled products.Huda also manufactures a variety of environmental chambers that simulate other climatic conditions such as rain, wind, dust and sun.If you have any questions,contact us please.

Contact:Mr.chen.

Phone: +86-1345054137/86-769-89201493.

Email:eden@hudatest.com.

Website:http://www.hudatest.com/.