Working Principle And Advantage Of High Temperature And Pressure Water Spray Test Chamber

The waterproof test chamber throughout the box with the overall structure, divided into upper, lower and right three parts, the upper part of the studio, the lower part of the machine room, the right is the electrical control cabinet. Selection of high-quality materials, the use of advanced technology processing molding, both inside and outside the shell are made of high quality SUS304 stainless steel plate. Indoor sample rack and other accessories are made of stainless steel fittings, reasonable design, durable. High pressure water spray assembly / working rotary table / electrical controller part of the composition.

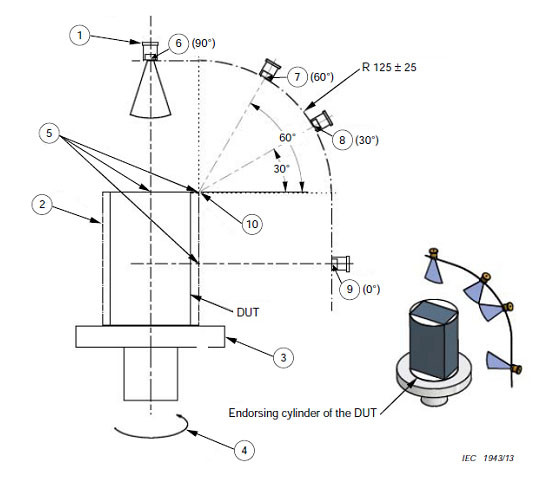

Sample rack design load 20 kg, horizontal 360 degree rotation. Transmission device design is reasonable, sophisticated production, driven by the advanced stepper motor plus reducer, can be set directly in the touch screen instrument speed, controlled by the PLC controller, easy to operate, to avoid the previous similar equipment, artificial sense of the inaccuracy of the adjustment and Cumbersome. The lower part of the turntable is equipped with a conductive slip ring. The sample can be energized during the rotation test. The test piece can be connected with 10A, 10 ~ 24V power supply without affecting the rotation of the turntable. Voltage drop <2V.

The equipment is equipped with a large enough water tank for water use. The suction motor pushes the water in the tank into the pipe and discharges it from the nozzle by adjusting the relief valve to maintain the specified flow and pressure. The pump is a high pressure piston pump, the nozzle is an inlet atomized fan nozzle

Flowmeter:

The electromagnetic flowmeter, composed of electromagnetic flow sensor and electromagnetic flow converter, which is based on the Faraday electromagnetic induction principle, can be used to measure the flow of test water flow, can achieve the flow control, regulation, display and total The Through the converter output 4 ~ 20mADC signal, and the central controller connected by its control, and display.

Contact:Lisa Zhong

Phone: +86-7698-1187866,+86-13829267288.

Email: manager@climatetester.com.

Website:http://www.climatetester.com/