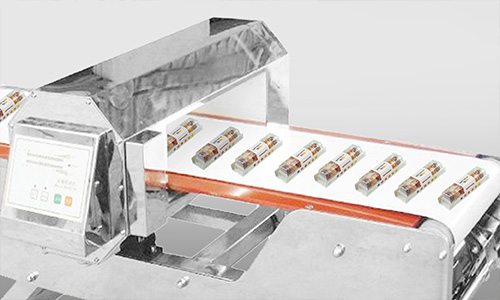

A metal detector machine solution with technology and expertise that can provide highly accurate, reliable and easy to clean.We are a food metal detector manufacturer, Syndar safeline metal detector uses the principle of electromagnetic induction to detect magnetic or non-magnetic metals. The sensitivity of our SD-5 series metal detection systems exceeds industry standards, leading the international closed and complete detection coil system, strict, precise and precise automatic filtering detection system, super anti-interference ability, such as vibration, noise, etc., high-level dustproof , Waterproof (IP66) certification can detect all metals, such as iron, stainless steel, aluminum, copper, etc., highly sensitive metal detection equipment is especially suitable for the food industry and other industries. It can be installed on a belt or chain conveyor belt as a metal detector conveyor machine, and can also be combined with an automatic checkweigher and rejection system, which can be quickly and easily integrated into your processing or packaging line, providing manufacturers in the smallest space Maximum quality control.