Dynamic checkweigher challenge test product inspection, integrated into an online automation solution, high-speed fault detection and product scrapping, with our checkweigher system, you are in the best position in terms of quality assurance and performance. We always pay attention to all laws and regulations, you can pass all completeness checks, and can quickly detect the facts of underfill and overfill, which is very beneficial to you as a manufacturer.

We provide solutions for dynamic online checkweighing, static checkweighing, metal detection, X-ray inspection and security inspection equipment, including combined systems

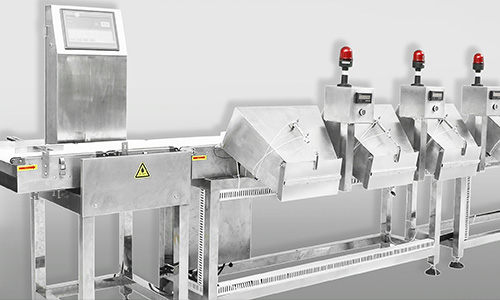

Dynamic online checkweigher can be combined into a positive and negative checkweigher, automatic weighing and labeling and scanning code integrated machine, automatic weight sorting scale, metal checkweigher, visual and X-ray inspection system or metal detector, in our The latest technology in the product portfolio. So that any industry can achieve the challenge, the product can be integrity checked.

The simple product learning algorithm in Dynamic checkweigher equipment can easily complete the settings of different products

Properly integrated into the process, our Combined system automatic checkweigher product enables you to consistently achieve the highest speed and best quality. As you know, for individual inspections of products, you only have a few seconds for precise transportation, positioning and inspection. Therefore, with our checkweigher system, you are in the best position in terms of quality assurance and performance.

Put forward your needs, we will consider and design a combination machine consisting of a checkweigher and x ray inspection system or a sorting machine, so that you can also modify it according to your needs. And, we will design the system to be as compact as possible, taking into account your space constraints.